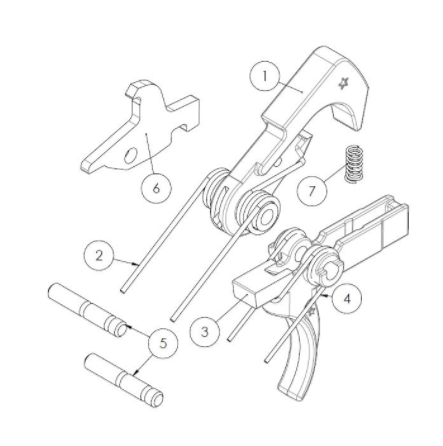

Description

After that, the BCM PNT™ Trigger and PNT™ Hammer then goes through a 3 step heat treat and case hardening process for optimal grain structure alignment, yielding a stronger and more wear resistance product.

Polished

The sear engagement surfaces are ground, but then hand polished for an increased smoothness and reduction in friction up to 300% beyond the Mil-Spec.

Nickel

An electroless nickel finish is applied for a smoother trigger pull with less ‘grit’ and reduced felt ‘creep’. Nickel also provides a long lasting finish that will not corrode, rust, or discolor due to oxidation.

Teflon

Teflon particles are embedded in the nickel, further reducing the friction of the interface and ensuring a long lasting coating. This is done on both the BCM PNT Trigger and Hammer in order to provide the maximum benefit allowed by the nickel coating, by augmenting the low friction and corrosion resistance.

This assembly includes our impact resistant trigger and hammer pins. They are centerless ground to a fine finish and superior tolerances to ensure compatibility with all MIL SPEC lower receivers built per the USGI TDP.

The BCM Disconnector is stamped from a 1070 material and fine blanked for cleaner edges, double disc ground to precise size. All hammer engagement surfaces are also ground for a super clean reset.

The processes and tolerances are matched in the BCM PNT™ Trigger Assembly to create a system better than the sum of its parts.

As with all BCM products, Made in the USA.

Reviews

There are no reviews yet.